After the taxonomy process, that

results in a classification of equipment in systems,

subsystems and components, we start the RCM analysis based in SAE JA 1011.

The first step is to establish

comprehensive alphanumeric equipment identification. Then, we can start to give

answers to the first five questions of the SAE JA 1011.

The questions are:

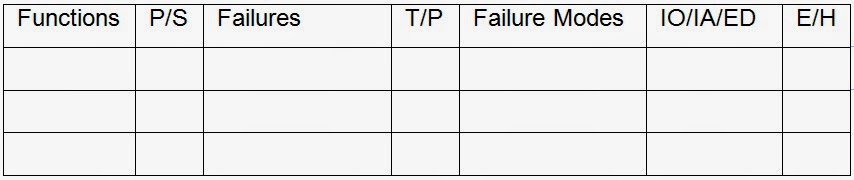

1. What are the functions and associated desired

standards of performance of the asset in its present operating context?

Answers must include all the functions of the asset under the operating context and the level of

performance desired.

These functions can be divided into Primary Functions or the reason why the organization acquires the

asset, and Secondary Functions or

other as environmental integrity, safety/structural integrity, control/containment/comfort, appearance, protective devices and systems, economy/efficiency, and superfluous.

|

| FMEA - 1 |

2. In what ways can it fail to fulfill its functions?

These are the failed states associated with each

function; they can be Partial or Total Failures.

|

| FMEA - 2 |

3. What causes each functional failure?

These

are the failures modes reasonably

likely to cause each failure. Lists of failure modes can include failure modes

that has happened before, that are currently being prevented, or that are

credible in the operating context that can be obtained from technical reports

or databases.

Recommend

databases for mechanical components are the OREDA – Offshore Reliability Data –

Handbook by Det Norske Veritas, and the Handbook of Reliability Prediction

Procedures for Mechanical Equipment by the Naval Surface Warfare Center –

Carderock Division, this last handbook also includes the effects of failures data.

Other

sources are the results of Root Causes Analysis of unidentified failures.

The failure modes can be classified into one of the following categories: Incorrect Operation, Incorrect Assembly, or External Damage.

To define if a failure mode is Evident or Hidden under normal circumstances is crucial to continue with the analysis and define the best task or action.

|

| FMEA - 3 |

4. What happens when each failure occurs?

The answers describe what would happen if no specific tasks are done to anticipate, prevent, or detect the failure. The Failure Effects include all the information needed to support its evaluation, such as evidence that the failure has occurred, if it can kill or injure someone, or to have an adverse effect on the environment, to have an adverse effect on production or operations, physical damages, or what must be done to restore the function of the asset.

|

| FMEA - 4 |

5. In what way does each failure matter?

These are the failure

consequences that must take into account if they are consequences of hidden

failure modes; and if they have safety and/or environmental consequences or

only have economic consequences.

|

| FMEA - 5 |

At this point, we can consider

finishing the full FMEA – Failure

Modes and Effects Analysis - giving values to Probability (of the failure mode), Detection (of the failure) and Severity

(of the failure consequence) and multiplicity them to calculate the RPN - Risk Priority Number-. This is the

methodology most commonly used in RCM analysis. The standard SAE J 1739 gives

us a methodology to perform an effective FMEA.

|

| FMEA - 6 |

Another option is to use the COFA – Consequences of Failures Analysis

– the methodology proposed by Neil B. Bloom that defines a Component Classification, based in an RCM COFA Logic Tree, that

classify the components in Critical, Potentially Critical, Commitment, Economic, or Run-to-Failure.

The COFA methodology is more

straightforward and comprehensive than FMEA to give a final component

classification to support the choice of the best maintenance tasks or actions, keeping

all the SAE JA 1011 standard requirements.

|

| COFA |

No comments:

Post a Comment